Modified Ender 5

Introduction

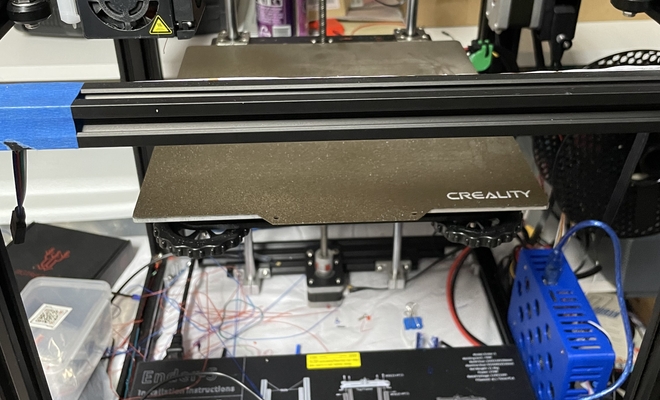

This is my Ender 5, a printer I’ve had since 9th grade. I’ve included it since there has been a longstanding process of fixing it, researching 3D printers, and upgrading it. Through this printer, I’ve gained nearly all my current knowledge on FDM 3D printing.

Repairs and Modifications

Throughout the lifespan of this printer, a few things have broken and been replaced. For instance, the hotend was damaged. In the process of researching replacements, I learned that I could print materials at higher temperatures using an all-metal hotend. This allowed me to start experimenting with materials like PETG. In this experimentation, I also ruined a smooth PEI build plate, as the two materials are known to fuse. Thus, I researched comparable alternatives for PETG, landing on a textured PEI sheet.

I have elected to make upgrades such as a geared extruder, Raspberry Pi server for remote control of the printer, custom 32-bit mainboard, and auto-bed leveling. These have all made my printer more reliable, and even quieter.

Hotend

The Ender 5 hotend.

Pictured above is the all metal hotend with a BLTouch attached. I chose the BLTouch for auto-bed leveling I find that it has the least drawbacks of any system. The main concern is that its mechanical parts may wear over time, but in exchange, it is bed-type agnostic, unlike inductive or capacitive sensors. This means that I can swap the bed out with no worry that the sensor or Z-offset will need to be adjusted.

Raspberry Pi Server

The Raspberry Pi mounted to the printer.

This Raspberry Pi server runs OctoPrint, allowing me to control the printer and check its status on the local network. Handy, since my printer is in the basement!

32-bit Mainboard

The 32-bit board mounted to the printer.

This is a BigTreeTech SKR V1.3 with TMC2208 Stepper Motor Drivers. The purpose of this is threefold:

- More space for custom firmware (useful for auto-bed leveling and other advanced features)

- More physical expansion (useful for auto-bed leveling)

- Near silent operation (thanks to the TMC2208 drivers)